|

Replacing a perished fuel return hose |

Almost nine months after we moved on board, Ravensdale is hopefully seaworthy.

All the problems flagged up by our diesel engine course have now been rectified.

And we are so glad we delayed taking her out to

sea until after John Parlane, of Morecambe-based Bay Sea School, came to our

boat in Maryport Marina, Cumbria, to do the RYA course with us.All the problems flagged up by our diesel engine course have now been rectified.

While teaching us how her two 300hp Volvo Penta diesel

engines work and how to maintain them, he spotted a number of things that

needed correcting before she left the marina.

We also discovered we didn’t have the tools we needed to

work on our engines as Phil’s tools were AF imperial and useless on a

Dutch-built boat where all the nuts and bolts are metric.

We went out and bought new tools and immediately ordered

the necessary engine parts.

|

One of Ravensdale's engines |

These started to arrive on Wednesday and Phil has spent every

day since in the engine room fitting the various parts and dealing with another

problem, which occurred while he was working down there.

I did offer my services in the engine room, seeing as how

I also have a certificate proving that I successfully completed the RYA Diesel

Engine Course, but he said he was happy to do it, if I would hand him the

relevant tools.

I can’t help thinking I got the best end of the deal and

I certainly wasn’t complaining as I now know just how cramped and uncomfortable

working down there can be.

Initially, we were going to wait until we had all the

parts to get it all done in one go.

It was a good plan, but like all good plans it didn’t

work :-(

In the meantime, Ravensdale’s hull and topside were given

a thorough clean to remove the dirt that was beginning to build up since she

has been back in the water.

|

Cleaning Ravensdale's starboard side |

|

Cracks in the perished fuel hose |

And we made sure that everyone who has commented on the

fact we have not taken her out to sea yet was aware that she does move – even if

it was a case of using ropes to pull her over to the neighbouring pontoon to

enable us to clean her starboard side J

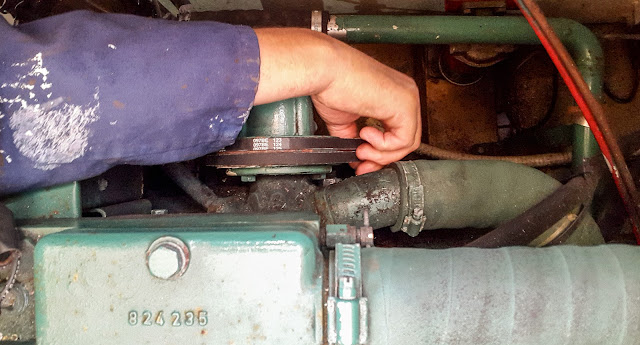

New drive belts for the alternator and water pump on the

starboard engine arrived on Tuesday and we collected a new fuel return hose for

the same engine from Forth Engineering in Maryport on Wednesday morning.

We thought we now had everything we needed to get on with the task in hand.

|

The replacement return fuel hose and a spare |

As soon as we got back from Forth Engineering, Phil

donned his coveralls and we lifted the floor of the saloon to provide access to

the engines from above.

He quickly replaced the perished fuel return hose and

removed the worn drive belts.

Then we discovered we had a problem.

The part numbers on

the old drive belts, which come in pairs, were not the correct ones for our

engines, so the supplier gave us the correct numbers, or so we thought, and we

ordered the ones they recommended.

The water pump belts fitted perfectly. However, the

alternator drive belts were much too long.

A quick call to the supplier revealed that there were two

types of alternator fitted to these engines, with the ones requiring the longer

belts being the more common of the two. They therefore assumed these would be

the ones we needed, but it seems this was not the case.

The company immediately sent out the correct belts, which

arrived yesterday, and the wrong belts have been returned.

Meanwhile, Phil fitted the water pump drive belts on

Wednesday and tightened some loose connectors on the battery terminals, then had

to give up until the replacement belts arrived.

|

Removing the old water pump drive belts |

Soon after he had emerged from the engine room and we put

the floor back, restoring a bit of normality to our sitting room, I tried to

run some water to make a coffee. A small amount of water came out of the tap

then it spluttered and stopped.

We tried running water a few more times without success,

then Phil went back down into the engine room (via the opening under the steps

to the aft cabin to save lifting the floor again) to see if he could find out

what had gone wrong.

And he discovered that, while working on the starboard

engine, he had knocked the pipe off the domestic water pump and it was pumping water out

into the bilges instead of through the taps.

We turned the pump off and he tried to sort it, but the

pipe to which it had been attached was split and was not long enough to cut

back so would need replacing.

We spent another night without running water, making do

with a jerry can full of water filled from the tap on the pontoon.

And, as if to add insult to injury, it started pouring

with rain at the same time.

For some reason, whenever we're without running water on

board, it starts falling out of the sky J

While trying to sort the water problem, Phil discovered

that, within a four-foot length, there were three separate hoses connected

together with copper tubing and associated jubilee clips for no apparent reason.

He decided they would be better replaced with one

length of hose so, on Thursday morning, we headed off to Forth Engineering

again to buy a suitable replacement and some new stainless steel jubilee clips

to fix it in place.

On our return, we lifted the floor again so he could get

into the engine room to carry out the work and restore our water supply.

|

Changing the water pipe |

|

The new impellers and extraction tool |

He also fitted new water pump impellers to both engines

after discovering they had not been changed or checked when we had the engines services in

December of last year. It was obvious that this was the case as the screws

holding the covers in place had been painted over some time ago and

had not been removed since.

Removing the old impellers, which are a series of vanes

moulded around a hub, proved a difficult task as the removal tool we had bought did not fit the old impellers. Replacing them with the new

ones was even more difficult.

But, after a bit of experimenting, Phil found a way of

doing it much more easily.

He tightened a cable tie around the vanes before

inserting the impeller into the housing, cutting them off when it was half way in. He was

then able to push it in the rest of the way.

He also refilled the greaser for the stern glands, which

keep the propeller shafts watertight.

|

Refilling the stern gland greaser |

And we've started collecting up all the spares we need to carry in case we have a problem at sea.

So Ravensdale is now seaworthy, or at least we've done everything

we can do to make her as seaworthy as possible.

All we need now is some good weather to coincide with the

tides so the marina gate will be open at a time when we want to take her

out into the Solway Firth.

We've also sorted through all Phil’s old tools and

managed to find some that could go to make room for the new ones as

space is finite when you live on a boat.

|

Sorting through our old tools |

|

Grey mullet swimming around in the marina |

On the wildlife front, we've been watching the grey

mullet swimming around in the marina, some of which are getting quite big now.

But they didn’t seem interested in the bread we threw into

the water to try to attract them to the surface to have their photographs

taken.

|

Swans - but no cygnets |

And a pair of swans continues to pay regular visits to the marina, but

without any cygnets.

We are not sure whether this is the same pair that brought

three cygnets into the marina last month. Hopefully not as this would mean that

they've lost their young.

|

One of the many beautiful sunsets we have enjoyed lately |

No comments:

Post a Comment