|

Phil and a friend apply the new trident logo on Ravensdale's bow |

Ravensdale is still high and dry almost five weeks after she

was lifted out of the water for her spring beauty treatment.

We initially intended her to be out on the hand standing

for about a fortnight – three weeks at most – to paint the underwater area of

her hull with antifouling paint, check her anodes and to generally clean and

tidy her up.

|

Ravensdale on stilts |

But she is still on stilts, making us very glad we

decided to pay for the impressive scaffolding steps that enable us to get on

and off the boat while her deck is around 14ft off the ground.

The alternative would have been to climb up and down a

ladder, which would have been fine for a short while, or if we were staying

elsewhere while doing the work, but not great when living on board, especially

if you need to visit the marina’s toilet facilities in the middle of the night!

We’re also becoming rather accustomed to life on dry land

– so much so that I’m wondering if it will be a bit of a shock to the system

when we end being rocked to sleep by the waves again.

Other than the lack of a toilet we can use on board (my

fault for being ill so soon after the lift-out), the biggest pain is that we

have no wifi on the boat.

This means going to the customer lounge every time we

want to do anything online and we have been too busy to do this by day and

often too tired to go over there in the evenings – hence the lack of blog posts

on my part.

Anyway, we’ve been getting on with the work we wanted to

do and a lot more that we didn’t plan, or in some cases even think of, before

the lift out on March 24.

|

Phil applies rubbing compound to the port side of Ravensdale's hull |

Phil has spent days using rubbing compound on the hull to

remove any marks and scratches, before polishing it to make her shine.

|

Polishing the hull to make it shine |

I’ve finished off cleaning the windscreen wipers, which

were proving very difficult to get bright and shiny until I bought some Brillo

Pads – now there’s a blast from the past! I remember cleaning pots and pans

with them as a kid and had no idea they were still in production, but

apparently they are and they’re brilliant!

We bought new blades for them and they are now back in

situ so we’ll be able to see while travelling in the rain, which can come in

very handy given the British weather.

I also touched up any areas of antifoul and boot top line

that needed tidying up and put several coats of white gloss on two strips of

wood attached to the bow (I still don’t know what they do, but they certainly

look better now than they did).

And I used several more grades of sandpaper on the prop

shafts to make them even smoother and shinier than I had achieved with my

previous attempts.

|

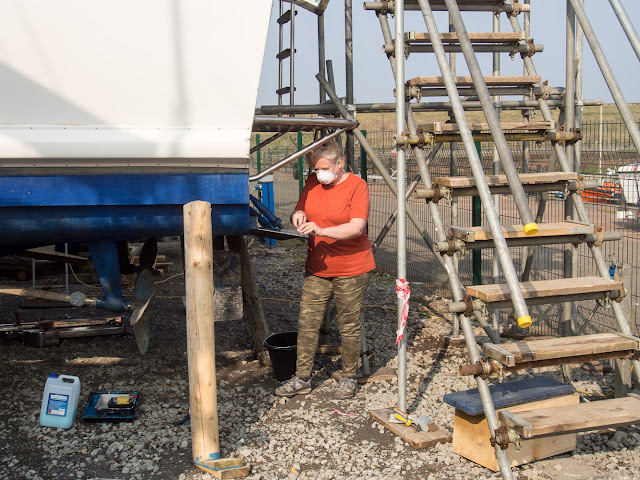

This image was taken when I started cleaning up the prop shafts |

Meanwhile, Phil has sent me some photos he took when I

started work on the prop shafts that I had completely forgotten he had taken.

|

Phil and Tony putting up the new bow logo |

Phil painted the blue lines around the top of the hull

and the superstructure and sprayed a second coat of paint on the propellers.

He also set about applying the new Neptunus trident logo

to the bow and, as it was the first time he had done this, he was very grateful

when another boat owner here – Tony – offered his assistance and asked if I had

a hairdryer they could use. And between the pair of them they did a great job.

We initially planned to use thin black tape for the lines

either side of the blue line around the top of the hull, as that was what had

been done previously, and ordered them from the same firm that supplied the

trident logo.

However, when Phil started putting them on, it quickly

became apparent that it was not going to work. We had measured the tape we took

off, but had not realised it covered black paint that was thicker than the tape

in some places.

|

Applying the black vinyl tape |

We considered ordering more, wider tape, but had already

spent a lot of money on tape that we could now not be able to use, so we

decided to buy black paint, tape the lines ourselves and paint them on and it

looks much better than the tape we bought would have done.

|

Painting the black stripes around the top of the hull |

Another little job that I decided needed doing was to

clean the fenders so I took them all down onto the hard standing and painted

them with Chine Shine. I then gave them a good scrub and washed them off.

They’re never going to be perfect again as they’ve

discoloured a bit over the years, but they look a lot better than they did and

still work so will not be replaced at this stage.

The work we intended to do has more or less gone to plan

– apart from minor delays caused by my being unwell and the days we have been

unable to get on as we would like outside due to high wind and/or rain.

But several things have conspired against our getting

Ravensdale back into the water sooner.

We have been waiting for MPM, the boatyard at the marina, to come and put in

the outlet that will give us the ability to discharge the holding tank from one

of the heads while at sea.

At long last, the part of the job that had to be done

while out of the water was completed yesterday. It will be completed once the

tank has been pumped out when we go back in.

Also, Phil had hoped to be able to get the depth sounder

on the boat working in, but this proved impossible.

And, although we found a paddle wheel on the underside of

the hull, which should provide information on speed and distance to a log,

there is no instrument onboard able to receive this data, so we have now bought

a dual purpose depth sounder/log that will need to be fitted before we can put

Ravensdale back in the water.

Meanwhile, there has been a lot of activity in the area

due to a serious fire on a nearby industrial estate when a factory that makes

artificial grass went up in flames on Tuesday of this week. Thankfully no one

was hurt, but the building was destroyed by the fire.

|

The factory fire taken from our fore deck |

We had a clear view of the blaze from our boat and could

see flames leaping as high as nearby trees, with clouds of thick, black smoke

towering above them.

Firefighters were drafted in from all over Cumbria and,

at the height of the fire, there were 12 fire appliances in attendance.

|

Pumping water out of the marina |

As the marina is fairly close by – less than half a mile

– from the fire, the fire service pumped water out of the marina along a pipe

that stretched all the way to the scene.

We could hear the pump running all night and it was still

being used yesterday as smoke continued to rise from the fire scene. Today fire

crews are packing it up ready to take it away.